Development Technology of Cholesterol Lowering Cheese

Abstract – The aim of this study is to determine the development technology of cholesterol lowering cheese. The strains of lactic acid bacteria with cholesterol lowering ability was used as the stater cultures of AM2-6 and BM2-5. According to the Box-Behnken design, the most desirable conditions were as follows: when the pasteurization temperature on 75℃ for 15 s, the inoculation rate of production starter cultures of AM2-6 and BM2-5 was 2:1, and the inoculum at 5 g/100g. The coagulation temperature was under 39.00℃ and rennet addition was 0.020 ml/100g. Compared to the actual operation, the prediction was at 89.6%. The results of the orthogonal experiment by Box-Behnken design was similar to the actual operation.

Introduction

In modern nutrition concept, functional foods are defined as the food and beverage products that derived from naturally occurring substances or those similar in appearance to potentially helpful products (Otles S. et al, 2012). It includes any modified food or food ingredient that provide specific benefits and/or reduce the risk of disease beyond nutritional functions (Roberfroid, 1999a). Functional foods contain many types of foods, such as cereals, dairy foods, baby foods, baked goods, meat products, spreads, confectionery, ready meals, snacks, and other alcoholic beverages (Subrota H. et al, 2019).

According to the previous report by Saxelin M. et al, 2003, dairy food products can be classified into three groups. One is the classical milk products, such as yogurt, cheese, butter and ice cream, etc. One is the value added milk products, including low-lactose or non-lactose products, hypoallergenic formulae milk and enriched milk fortified with vitamins, etc. One is the functional dairy foods. That is the dairy products enriched with functional food ingredients. It should originate from dairy and/or non-dairy sources and have proper health benefits beyond their basic nutritional values.

Cheese is regularly defined by FAO/WHO as following definition: cheese is the fresh or fermented dairy products made from milk, butter, partially skimmed milk, buttermilk or those mixtures, through curd and excluding whey (Gu R. X., 2010). This process is the coagulation of milk protein casein (GB 5420-2010). The properties of fermented cheese are similar to the common yogurt, it is made through the fermentation process and rich in lactic acid bacteria. But the concentration of cheese is higher than yogurt as solid, almost one kilogram of cheese is concentrated from ten kilograms of milk. Therefore, the fermented cheese has a richer nutritional value.

Rennet which taken from the fourth stomach of yak is an essential prionase for cheese production. The addition of rennet is to promote the curd of raw milk and to exclude the whey. The addition of CaCl2 is to regulate the salt balance and to promote the formation of clots. The addition of salt is to improve the flavor, texture and appearance of cheese, and to exclude internal whey or moisture, increase cheese hardness, limit the activity of lactic acid bacteria, regulate the formation of lactic acid and the maturation of cheese, prevent and inhibit the proliferation of bacteria (Gu R. X., 2010). In cheese production process, several factors, such as inoculum of starter cultures, pH, salting, ripening, decrease of water activity, packaging etc. might influence the functional activities of probiotics

(Alessandra P. et al., 2017).

Development technology of cholesterol lowering cheese was produced under the fermentation process of traditional cheese production with some modification. Strains of lactic acid bacteria with cholesterol lowering ability was provided by Key Laboratory of Dairy Biotechnology and Engineering, Ministry of Education, China and was used as the stater cultures. Pasteurization temperature of raw milk, optimal inoculum and rate of starter cultures, optimal coagulation temperature and the addition of rennet will be selected as the parameter to be confirmed in the development technology of cholesterol lowering cheese through the determination of pH, titradable acidity and viable count.

Material and Methods

1. Production process of cholesterol lowering cheese

Freeze dried cells of the Lb. plantarum strains AM2-6 and BM2-5 with cholesterol lowering ability were used as the production starter cultures for the development technology of cholesterol lowering cheese (provided by Key Laboratory of Dairy Biotechnology and Engineering, Ministry of Education, China). The cholesterol lowering cheese was produced according to the traditional production process of cheese with some modification (GB 5420-2010). Raw milk of cheese was prepared according to GB 19301-2010.

2. Determination of pasteurization temperature

Raw milk was pasteurized under different condition during the cholesterol lowering cheese production process. After rapidly cooled to the inoculation temperature, the production starter cultures was inoculated and prefermented. Stirred, added CaCl2 and rennet. Cut and heated again to exclude the whey. Finally, salted and pressed the cheese into a mold (Yang Y. et al, 2009). The pH value was determined as mentioned above. Curd texture and clot color was observed.

3. Determination of optimal inoculum of starter cultures

The cholesterol lowering cheese was produced as mentioned above. The production starter cultures was inoculated at different inoculum. The pH value was determined. Curd texture and clot color was observed.

4. Determination of optimal rate of starter cultures

The cholesterol lowering cheese was produced. The production starter cultures was inoculated with different rate. The pH value was determined. Curd texture and clot color was observed.

5. Determination of coagulation temperature

The cholesterol lowering cheese was produced. Curd under different temperature, then exclude the whey. The pH value was determined. Curd texture and clot color was observed.

6. Determination of addition of rennet

The cholesterol lowering cheese was produced. The addition of rennet was different. The pH value was determined. Curd texture and clot color was observed.

7. Box-Behnken design of cholesterol lowering cheese

The optimal production process of cholesterol lowering cheese was obtained through response surface experiment design. Box Behnken Design was performed using the Design-Expert 8.0.6 software.

8. Physical and chemical analysis of cholesterol lowering cheese

The cholesterol lowering cheese was produced under the optimal conditions. Physical and chemical analysis of moisture was determined according to GB 5009. 3-2016. Protein, fat and ash was determined according to GB 5009. 6-2016, GB 5009. 5-2016, and GB 5009. 4-2016, respectively. Amino acid were determined using L-8900 amino acid analyzer according to GB 5009. 124-2016. Concentrations of vitamins A were determined by RP-HPLC according to GB 5009. 82-2016.

Concentrations of vitamins B1 were determined by RP-HPLC according to GB 5009. 84-2016. Concentrations of vitamins B2 were determined by HPLC according to GB 5009. 85-2016.

9. Sensory evaluation of cholesterol lowering cheese

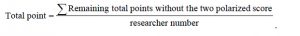

Sensory evaluation was performed by seven trained researchers after milk fermentation. Sample preparation, laboratory and personnel requirements, evaluation items, standards and methods, data processing was analyzed according to RHB 506-2004. Briefly, took 50 g of cheese samples out on the plate, then tasted and smelled (0-50 points). Researchers gargled with warm water after smelled, then tasted. The color and exterior was observed under the light (each 0-10 points). The texture was observed and evaluated according to the sense of touch (0-30 points). One hundred points system was used to evaluate the cheese. Removed the highest and the lowest point of evalution, the total points were calculated through the following formula:

10. Storage of cholesterol lowering cheese

The cholesterol lowering cheese was refrigerated and stored under 4℃ for 90 days. The main physical and chemical index was determined during storage. The pH value and amino acids were also determined.

Results and Discussions

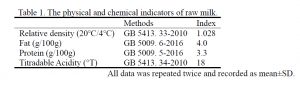

1. Pretreatment of raw milk

Raw milk was pretreated under GB 19301-2010. The freshness of raw milk was tested by 72% ethanol, and no flocculation appeared. The physical and chemical indicators of raw milk was determined and shown in Table 1.

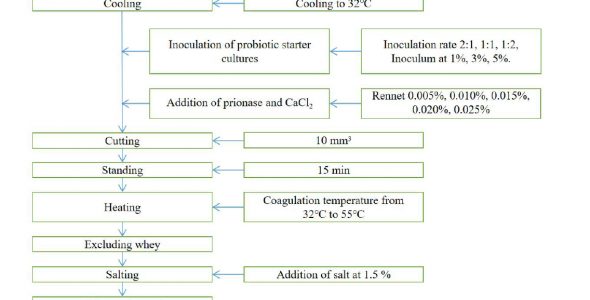

2. Processing technology of cholesterol lowering cheese

The cholesterol lowering cheese was produced using the production starter cultures of the Lb. plantarum strains AM2-6 and BM2-5. Raw milk was pretreated and standardized. After sterilization, raw milk was cooled to 32 ℃. The starter cultures was inoculated, CaCl2 and rennet was also added during stirring. After cut into 10 mm3, stand for 10 min. The coagulation temperature for curd was from 32℃ to 55 ℃ for 90 min. Then excluded the whey, salted and pressed the cheese into a mold for 12 h at room temperature. The flow chart of processing technology of cholesterol lowering cheese was shown in Fig 1.

Fig 1. The flow chart of processing technology of cholesterol lowering cheese.

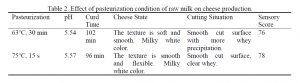

3. Determination of pasteurization temperature

The cholesterol lowering cheese was produced as mentioned above. Raw milk was pretreated and standardized. Sterilized under 63℃ for 30 min and 75℃ for 15 s respectively. Then cooled to 32 ℃. The production starter cultures was inoculated at the rate of 1:1, the inoculum was 3%, CaCl2 and rennet was also added during stirring. After cut into 10 mm3, stand for 10 min. The coagulation temperature for curd under 32℃. Then excluded the whey, salted and pressed the cheese into a mold for 12 h at room temperature. The pH value was determined and sensory evaluation was evaluated. The effect of pasteurization condition of raw milk on cheese production was shown in Table 2. According to the sensory evaluation, 75℃ for 15 s was selected as the optimal pasteurization temperature of raw milk during cheese production process.

4. Determination of optimal inoculum of starter cultures

The cholesterol lowering cheese was produced. Raw milk was pretreated and standardized. Sterilized under 73℃ for 15 s. Then cooled to 32 ℃. The production starter cultures was inoculated at the rate of 1:1, the inoculum was 1%, 3%, 5%, respectively. CaCl2 and rennet was also added during stirring. After cutting, stand for 10 min. The coagulation temperature for curd under 32℃. Then excluded the whey, salted and pressed. The pH value was determined and sensory evaluation was evaluated. The effect of inoculum of starter cultures on cheese production was shown in Table 3. Inoculum of 5% of starter cultures was the optimal inolulum during cheese production process.

5. Determination of optimal rate of starter cultures

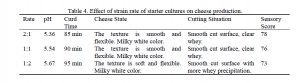

The cholesterol lowering cheese was produced. Raw milk was pretreated and standardized. Sterilized under 73℃ for 15 s. Then cooled to 32 ℃. The production starter cultures was inoculated at the rate of 2:1, 1:1, 1:2, the inoculum was 3%. CaCl2 and rennet was also added during stirring. After cutting, stand for 10 min. The coagulation temperature for curd under 32℃. Then excluded the whey, salted and pressed. The pH value was determined and sensory evaluation was evaluated. The effect of strain rate of starter cultures on cheese production was shown in Table 4. Strain rate of 2:1 was the optimal rate of starter cultures during cheese production process.

6. Determination of coagulation temperature

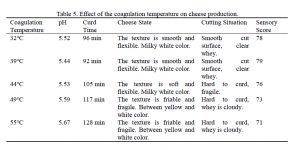

The cholesterol lowering cheese was produced. Raw milk was pretreated and standardized. Sterilized under 73℃ for 15 s. Then cooled to 32 ℃. The production starter cultures was inoculated at the rate 1:1, the inoculum was 3%. CaCl2 and rennet was also added during stirring. After cutting, stand for 10 min. The coagulation temperature for curd under 32℃, 39℃, 44℃, 49℃, 55℃ Then excluded the whey, salted and pressed. The pH value was determined and sensory evaluation was evaluated. The effect of the coagulation temperature on cheese production was shown in Table 5. Temperature under 39℃ was the optimal coagulation temperature during cheese production process.

7. Determination of addition of rennet

The cholesterol lowering cheese was produced. Raw milk was pretreated and standardized. Sterilized under 73℃ for 15 s. Then cooled to 32 ℃. The production starter cultures was inoculated at the rate 1:1, the inoculum was 3%. CaCl2 and rennet was also added during stirring. The addition of rennet was 0.005 ml/100g, 0.010 ml/100g, 0.015 ml/100g, 0.020 ml/100g, 0.025 ml/100g respectively. After cutting, stand for 10 min. The coagulation temperature for curd under 32℃. Then excluded the whey, salted and pressed. The pH value was determined and sensory evaluation was evaluated. The effect of addition of rennet on cheese production was shown in Table 6. Rennet of 0.020% was the optimal addition of rennet during cheese production process.

8 Box-Behnken design of cholesterol lowering cheese

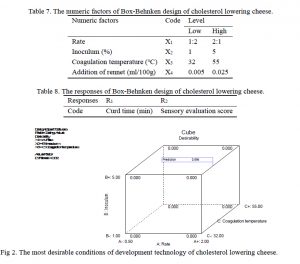

In Box-Behnken design of the optimal production process of cholesterol lowering cheese, 4 numeric factors and 2 responses were set. The 4 numeric factors were inoculation rate and the inoculum of the production starter cultures, coagulation temperature and addition of rennet (Table 7). And 2 responses were curd time and sensory evaluation score (Table 8).

According to the Box-Behnken design, the final equation in terms of coded factors was performed as the following formula:

R1 = +104.00 * X1 * X2 * X3 -3.75 * X4 +0.000 * X1 * X2 +0.000 * X1 * X3 +0.000 * X1 * X4 +0.000 * X2 * X3 +0.000 * X2 * X4 +0.000 * X3 * X4 +0.000 * X12 +1.25 * X22 +1.75 * X32 -3.75 * X42. R2 = +74.75 +0.63 * X1 +0.75 * X2 -0.88 * X3 +0.88 * X4 +0.000 * X1 * X2 +0.000 * X1 * X3 +0.000 * X1 * X4 +0.000 * X2 * X3 +0.000 * X2 * X4 +0.000 * X3 * X4 -0.13 * X12 -0.25 * X22 -0.37 * X32 +0.88 * X42.

The most desirable conditions combined the numeric factors on the responses according to the Box-Behnken design of cholesterol lowering cheese was as follows: when the pasteurization temperature on 75℃ for 15 s, the inoculation rate of production starter cultures of AM2-6 and BM2-5 was 2:1, and the inoculum at 5 g/100g. The coagulation temperature was under 39.00℃ and rennet addition was 0.020 ml/100g. Compared to the actual operation, the prediction was at 89.6%. The most desirable conditions of development technology of cholesterol lowering cheese was shown in Fig 2. The results of the orthogonal experiment by Box-Behnken design was similar to the actual operation.

9. Physical and chemical analysis of cholesterol lowering cheese

The cholesterol lowering cheese was produced under the optimal production process. The pasteurization temperature on 75℃ for 15 s, the inoculation rate of production starter cultures of AM2-6 and BM2-5 was 2:1, and the inoculum at 5 g/100g. The coagulation temperature was under 39.00℃ and rennet addition was 0.020ml/100g. The protein, fat, lactose, ash and moisture content of cholesterol lowering cheese was determined and shown as Table 9. Amino acid and vitamins A, B1, B2 was determined and shown as Table 10, Table 11. The physical and chemical index meet the physical and chemical properties of semi-hard cheese (C. L. Manuelian et al, 2016).

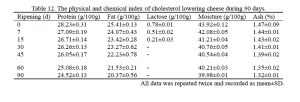

10. Storage of cholesterol lowering cheese

The cholesterol lowering cheese was refrigerated and stored under 4℃ for 90 days. The main physical and chemical index was determined during storage (Table 12). At different ripening stages, the protein, fat, lactose, moisture and ash content of cholesterol lowering cheese was significantly differed, p<0.05. And all components tended to decrease. The protein and fat content of cheese are gradually degraded. Lactose was almost impossible to detect in the later period, it indicated that the lactose was completely metabolized.

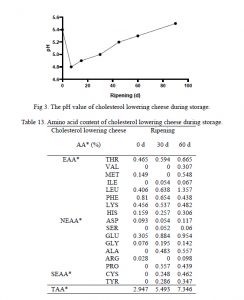

The pH value of cholesterol lowering cheese was determined during storage (Fig 3). During the production process of cholesterol lowering cheese, most of the lactose was excreted with whey during the curd period, and the remaining lactose was gradually metabolized into lactic acid during the cheese ripening. Lactic acid was completely consumed in the later stage of ripening. During the first week, the pH value was gradually decreased. It indicated that the starter cultures still growing, and lactose in the cheese still producing acid. After one week of ripening, the pH value began to increase. It indicated that most of the lactose had been consumed, and the protein was decomposed to produce some alkaline substances, such as ammonia. The pH value of cholesterol lowering cheese was slightly increased. As in Table 13, with the ripening of the cholesterol cheese, the types and the total amount of amino acids was increased.

Conclusions

The cholesterol lowering cheese was produced using the production starter cultures of AM2-6 and BM2-5. The optimal pasteurization temperature, optimal rate and inoculum of starter cultures, optimal coagulation temperature and addition of rennet was determined. According to the Box-Behnken design, the most desirable conditions combined the numeric factors on the responses of cholesterol lowering cheese were as follows: when the pasteurization temperature on 75℃ for 15 s, the inoculation rate of production starter cultures of AM2-6 and BM2-5 was 2:1, and the inoculum at 5 g/100g. The coagulation temperature was under 39.00℃ and rennet addition was 0.020 ml/100g. Compared to the actual operation, the prediction was at 89.6%. The results of the orthogonal experiment by Box-Behnken design was similar to the actual operation.

Acknowledgment

Specially grateful to the professor Menghebilige provided the relevant experimental conditions in the course of the completion of the present study.

Sarengaole1,2, Ch.Tsend-Ayush1, Bayinjirigala3, Monhebilige2

1 Food Processing Technology of Mongolian University of Science and Technology, Mongolia.

2 Key Laboratory of Dairy Biotechnology and Engineering, Ministry of Education, China; Inner Mongolia Agricultural

University, Inner Mongolia, China.

3 College of Animal Science; Inner Mongolia Agricultural University, Inner Mongolia, China.